In-House Offerings

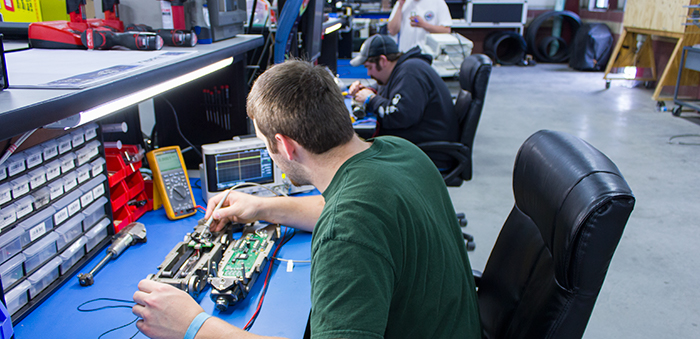

Rausch USA has developed a program of repair and maintenance training modules to help our customers improve service skills. Each module is offered at the Rausch USA service facility with our experienced Service Staff. Customers will be training on existing products at our facility. The descriptions and time estimates for each module are listed on this page. Bi-annual service training will be resumed/scheduled as soon as it is deemed safe to do so.

Cable Repairs

Program Details

The customer will be trained to properly diagnose and repair the three different types of push cables (black, gray, green), Rau7 orange lateral cable and Rau9 orange mainline cable. The proper procedures will be thoroughly taught and the procedures and tools used to do a quality repair will be demonstrated.

Time estimate – allow two hours for the first push / lateral cable, one hour for mainline cable.

L 135 Repair/Maintenance

Program Details

The customer will be taught how to repair the L 135 tractor based on their level of ability and resources in the field (this will vary between each individual/company). Trainees will be shown how to replace belts, motors, circuit boards and any seals or O-rings that could potentially cause a leaking issue. The customer will be shown how to routinely clean and lubricate the tractor to keep it in its best working condition. After the tractor repair discussion, we will demonstrate our final testing and leak testing procedures. NOTE: the procedures can be utilized on an L 100 tractor if applicable.

Time estimate – two + hours (can vary).

Lateral Launch Equipment Repair

Program Details

This training covers all of the tractor mounted equipment modules for lateral launching and the lateral cameras (PM 135, SKM 135, ZKM 135, and KS 60). This involves demonstrating all proper troubleshooting procedures for each piece and how to disassemble and repair them correctly. Subjects include replacing circuit boards, changing the camera module, replacing connector assemblies and seals / O-rings etc. Proper cleaning and lubrication of all equipment will be shown and after all proper repairs are made, final testing and leak testing will be demonstrated.

Time estimate – four + hours (can vary).

KS 135 Mainline/Laser Camera Repair

Program Details

This training will show the customer how to replace circuit boards, test the slip ring, replace the camera module and illumination components as well as fix leaks etc. on the KS 135 camera. Proper cleaning and lubrication will be shown along with final testing and leak testing procedures.

Time estimate – two + hours (can vary).

ECO Star / Proline Controls

Program Details

This category will review basic controls and adjustments within the ECO STAR and Proline control units. Customers will learn how to adjust different voltages and perform calibration on items such as lift and home positions, along with how those items may affect operation of the system.

Time estimate – one hour.

Overall System Testing/Repair

Program Details

The system as a whole will be reviewed with the trainees. Proper maintenance will be demonstrated and how to test for various issues on a complete system. We will setup various issues based upon requests and walk the customer through the different troubleshooting steps to fix and/or diagnose issues. Various tools and attachments that aid in these processes will be shown.

Time estimate – two + hours (can vary).

MinCAM Push Systems

Program Details

This training includes diagnosing, repairing and maintaining the minCam push systems. Cable repairs, camera repairs and troubleshooting of the entire unit will be shown. Proper operation and adjustments within the push system will also be displayed. The customer will only receive training on the model/s that they own.

Time estimate – two + hours (can vary).

Service Training Costs

The In-House Service Training Program is priced individually per class module per trainee. It can be individually scheduled anytime throughout the year, or at a discount during our bi-annual Service Training Days. Service Training costs are segregated into three levels. Please call Rausch USA for specific pricing information or Service Training dates.

Free Training

This is for customers who have in-warranty vehicles (those vehicles purchased from Rausch USA within the last 12 months). Please note that the free training must be scheduled during the advertised Service Training Days, held in October and April.

Half Priced Training

Training is offered at a half price discount to our out-of-warranty Rausch USA customers who schedule training during the advertised Service Training Days. For those with in-warranty vehicles that choose to schedule training outside of the Service Days, training is offered at a half price discount.

Full Priced Training

This training is for any customer that individually schedules a service training module outside of the Service Days.

What are Service Days?

There will be a week of Service Training held at Rausch USA two times a year. These are fixed dates. Out-of-warranty customers can sign-up and receive the discounted Service Day rates. Signing up for a full slate of classes can qualify for a further discount per trainee. Service Days are tentatively scheduled for one week in October and one week in April.

These are not set classes or times; they may run shorter or longer than the estimated time listed above. All of the training times on individual modules will vary depending on customer’s ability, number of trainees, resources and requests/questions. We will attempt to focus the training around the customer’s needs.

In-warranty training discounts are only eligible for up to 4 operators.

Rausch reserves the right to make changes to our training policy and process including scheduled training dates. Examples of potential reason for change could include attendance, weather, improvements, and availability of training personnel.